Knowledg Center

Knowledg

LED is an acronym for Light Emitting Diode – a special type of semiconductor that was initially used to replace standard lamps in early electronic equipment, later progressing to consumer electronics in the form of VCR and calculator displays. In the past decade, massive advances have been made in LED technology, with today’s high-power white tint LED’s commonly used in automotive/bicycle lighting, aviation, laptops and televisions, and even home lighting. LED technology is fast replacing older incandescent technologies

The LED advantage…

Energy savings LED's convert approximately 20% of their input power into light energy, compared to conventional incandescent bulbs which generally only convert about 2% of their input power into light. As a result, LED technology offers excellent energy savings over competing alternatives, making it a cost effective and environmentally-friendly solution for modern light-emitting devices.

Longevity The principle behind conventional incandescent technology is based on electrons travelling through a tungsten filament, causing the filament to generate temperatures of up to 2500 Celsius, with light energy merely a byproduct of this process. Due to this inherently inefficient design, incandescent bulbs rapidly deteriorate and burn out after about 1000 hours of use. LED’s, on the other hand, operate on an entirely different principle, and while they do require specialized components to achieve maximum brightness, a working lifespan up to 50,000 hours is possible, with a gradual fading of brightness rather than instant burn-out.

Durability Due to the absence of a delicate filament and thin glass bulb, LEDs can withstand shock and vibration far beyond that tolerated by incandescent lamps making them ideal for rugged and demanding applications.

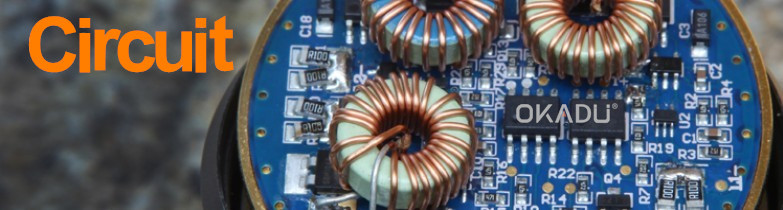

OKADU’s propriety regulation circuit is an essential component in every OKADU flashlight. The circuit’s unique power source management system delivers constant current to the LED regardless of battery condition/chemistry, resulting in continuous, unwavering light output for end users. The circuit’s efficiency and reliability is further enhanced by carefully engineered electronic components such as gold or silver plated contact points. Moreover, every OKADU flashlight features an integrated microcontroller unit which works in tandem with the regulation circuit to offer an intuitive and versatile user-interface.

A Led drive/regulation circuit is crucial in improving the efficiency of the 'power to light' conversion process, allowing for longer runtimes and more stable operation using various battery chemistries. OKADU's highly reliable and compact drive circuit is the reason OKADU flashlights run longer and shine brighter than the competition.

Every OKADU flashlight is constructed from light weight, high strength aero-grade aluminium alloy. Additionally, the majority of OKADU models are CNC machined from a solid aluminium bar. This manufacturing process gives OKADU flashlights their superior shock/impact resistance, with many lights able to withstand being rolled over by car or dropped from several meters onto a hard surface with no performance loss (not recommended as may void warranty). Compared to cheaper and weaker tubular aluminium flashlights produced by the majority of flashlight manufacturers today, OKADU offers significant gains in both ruggedness and performance. Furthermore, all OKADU models are treated with a military-spec type III hard anodized finish, making the flashlight surface as tough as diamond, thus protecting it from scratches, abrasions and corrosion.

About the ANSI/NEMA FL-1 standard

Why Create Standards Recently, a need for a standard performance platform for the flashlight industry was recognized. The absence of a consistent performance standard has made it difficult to provide comparable product claims and effectively communicate features and benefits, which consumers use to select the right flashlight for their specific needs. Our research indicates a consistent performance platform would be quite beneficial to help users make the right selection when choosing a flashlight. In addition, the category is changing rapidly as new companies and products enter the market. Flashlight technology has radically changed and consumers are eager to learn more about these new disruptive technologies. Current agencies, such as UL (Underwriters Laboratories), do not provide performance standards for flashlights, so major retailer’s that employ testing firms are requesting guidance.

Flashlight Standards To respond to this need, 14 famous flashlight companies collaborated to write a standard. They included the following products: hand-held/portable flashlights, spotlights, and headlamps. The ANSI/NEMA FL 1 Standard has been ratified and includes six measures. Each measure is defined, has a test procedure specified, and has an associated icon to use for claims. Standard ratification included voters representing three groups: 1) manufacturers, 2) users, and 3) general interests – one group cannot represent more than 50% of the total ratifying vote.

Here is information that is known from public sources. Performance of flashlights is measured using new batteries included with the light when purchased or, if no batteries are included, the batteries recommended by the packaging. There are six criteria used:

ANSI (American National Standards Institute)These standards are accredited by ANSI, which is a private non-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organization also coordinates U.S. standards with international standards so American products can be used globally.

CATEGORIES

CONTACT US

Contact: Jccms

Phone: +86 15338880086

Tel: +86 15338880086

Email: admin@jccms.cn

Add: Shenzhen longhuaixnqu